Protective Textiles based on Carbon Nanotube Composites (PROTECT)

The concept of the “PROTECT” project lies on the development of lightweight and flexible protective fabrics designated for personnel with high risk professions. The materials proposed, polyester composites with carbon nanotubes, possess enhanced mechanical properties and may result in fabrics with improved comfort.

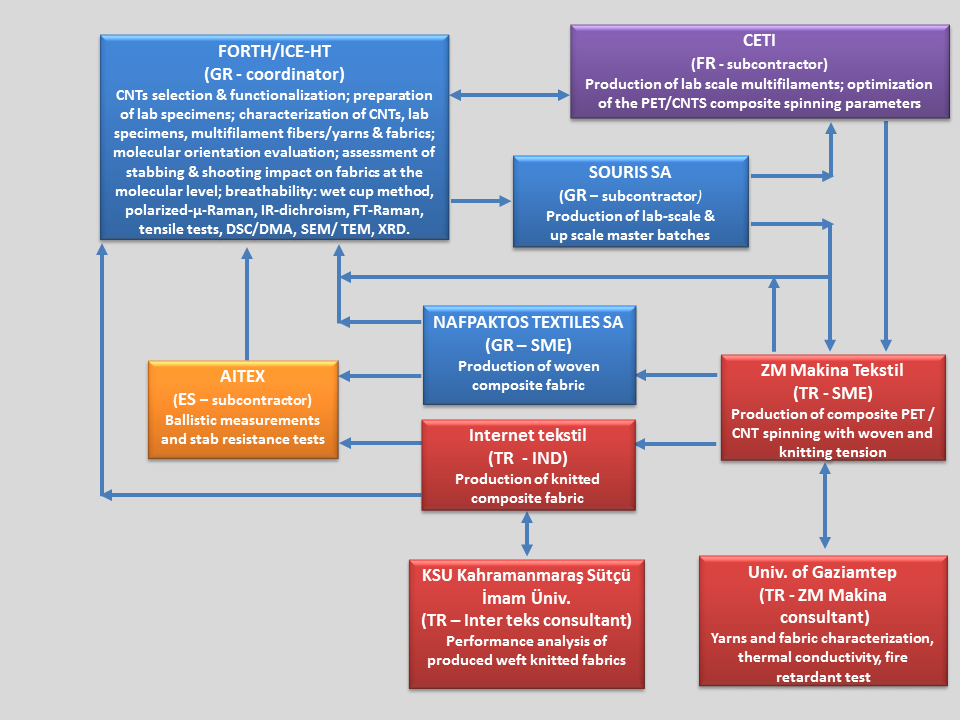

The former knowledge of the academic partners involved in relevant projects and especially in the optimization of similar composites forming monofilament fibers, along with the long-standing experience of the industrial partners on the production of multifilament fibers and on their subsequent weaving and knitting, ensure the best solution on the development of the targeted fabrics, whose efficiency will be validated after both bullet-proof and stab resistance tests.

Apart from the experience gained and the prospective given for the establishment of new market-targets, the project offers a great opportunity to trigger the productive units of each of the national regions involved to give emphasis on alternate products with high added value.

Objectives of the project

The concept of the PROTECT proposal is based on the development of lightweight and flexible smart protective clothing designated for daily use by high risk personnel. The ultimate objective is the improvement of the current technology and the development of more effective protective clothing and other textile based systems accessories whose main function is to protect the user.

Protective clothing for high risk personnel normally encloses body armour, uniforms, undergarments and gloves. In order to provide greater protection, textile may be reinforced with metal or ceramic; however, although these solutions can offer excellent stab and ballistic protection, they are relatively heavy and inflexible. Based on the exceptional electronic, optical, mechanical and chemical properties of carbon nanotubes (CNT), reinforced polymeric fibres with CNT will provide lighter and more flexible clothes (comparing to commonly used in practice today) with extra protection.

Ambition

The project is aiming in the development of lightweight and flexible smart protective fabrics that will replace current products that can be found actually in the market. Therefore, we reasonably consider that the appropriate incorporation of CNTs into PET, the optimized production of polyclonal yarns and their subsequent weaving/knitting can give rise to the development of new added value lightweight and flexible smart protective clothing. In this context, anticipating a beyond the state of the art perspective, we will exploit (a) the accumulated/standard experience of the consortium in the optimization of nanocomposite spinning parameters (CEFI subcontractor), adoption of polymer resins with convenient intrinsic viscosities, production at adapted denier per filament & draw ratio values to obtain highest tenacity and optimized CNT ratio (MK), (b) the sophisticated expertise of R&D partner and consultants in the evaluation of MWCNTs weight fraction in polymer nanocomposites and in the estimation of the molecular orientation of polymeric matrix & MWCNTs and in the assessment of stabbing & shooting impact on fabrics at the molecular level and even (c) the acquired experience in the manufacturing of MWCNTs/PET composites from the labscale film preparation to the upscale spinning fibre and in the functionalization of CNTs to be embedded in polymer matrixes. A note is made of the fact that PROTECT has the ambition to develop protective panels able to pass both bullet proof and stab resistance tests; something that is not at all trivial or obvious.

The protective textile market is increasing in the last years. There is a global competition especially between Asian and European textile multinational companies. Hence, any incentive research programme at the European level (that ensures better efficiency and coordination) will be beneficial for the strategic strengthening of EU in this particular market. In the field of protective textiles the challenge is the use of new materials that improve the overall properties of the fabric while decreasing the overall weight and endorse agility to the user. Fabrics based on CNTs reinforced PET fibers is an option that possesses the potential of fulfilling the challenges stated as they use low density materials which in principle exhibit striking mechanical properties taking into account both flexibility and toughness. In particular multifilament CNT reinforced PET fibers may be an excellent choice as: (i) multifilament fibers have in general superior macroscopic mechanical properties with respect to monofilament ones and (ii) despite the fact that a number of research studies indicate the enhanced monofilament CNT reinforced PET properties polymeric fibers, there is no known studies and/or commercial products based on similar weaved multifilament fabrics. Based on, (i) our previous knowhow of producing and characterizing monofilament CNT reinforced PET fibers (obtained within the “INPROTEX” project – LEADERA), (ii) the proof of concept that has already be drained from “INPROTEX” project, (iii) the contribution of top leaders with respect to their profile (from both research/academia and enterprises) in the proposal and (iv) the systematic and well defined methodology proposed to be followed by the partners participating in the current proposal we are confident that the tests on the proposed semi industrial scale multifilament weaved fabrics will be accomplished and validated.